Troubleshoot Your Grow - FAQs

Spores VS Liquid culture

Spores are much more prone to contaminating grain than a liquid culture is simply based on the methods of how spores are collected.

Inoculating your substrate with a liquid culture is a far better method because you know your culture is alive and viable.

You can see if there is any other contaminates growing in it.

We tell people to always start with a liquid culture if possible.

It will speed up your growing time because you do not have to wait for the spores to germinate and establish themselves, they are already alive and growing.

If you have any petri dishes or a way to make agar media it is always a good idea to make your own liquid cultures, especially if you already have the spores.

How many ccs does it take to inoculate a kit / bag

There is no exact answer to this question. We generally tell people that 2-4 ccs of solution should be sufficient enough to inoculate the two-pounds of grain in this kit.

This amount can vary depending on how potent your syringes are and whether you are using spores or a liquid culture.

Even though this kit is five pounds, you only need to inject enough solution to inoculate the grain portion of the kit, because the colonized grain will in turn later spread throughout the compost.

It is important to know that you must not to add too much liquid as this can over saturate the kit and will cause slow or no growth.

Can I use spores to colonize compost

Our compost works best when inoculated with colonized grain spawn.

If you just inject this bag with spores you will more than likely not see any growth.

Spores need some kind of nutritive substance like grain to take ahold of and establish mycelium growth first.

Start by injecting your spores or liquid culture into a sterilized grain medium (we have this for sale in our store), then once the grain is colonized you can transfer it to the compost, then once the compost is colonized the mushrooms will grow right out of the bag or you can transfer them to some kind of fruiting chamber, tote or terrarium.

Foreign debris in bags

Our compost is made in very large batches and because the grain as process on the same machinery that process other types of grain and feed we sometimes find foreign debris such as sticks, corn, beans and yes sometimes bugs.

It does not happen often but it is pretty much unavoidable.

Everything in the bags have been cooked and sterilized and we have never seen the presents of insects in the bags negatively affect mycelium growth. Mushrooms will grow on pretty much any decaying matter.

Slow/No Growth

There are two factors with slow growth of mycelium.

They are temperature and oxygen.

Make sure you are offering a hospitable environment for your strain of culture to flourish in.

Slowly raise the temperature day by day and watch for growth.

Add more air into the bag by gently pulling the bag sides back and forth, pulling more oxygen through the filter.

Our grain is produced in batches of about 400LBS at a time so it is pretty uniform.

Consistency is really something we strive for and is necessary for our products to work correctly.

I have noticed that the seasons and climate can affect the moisture content of the grain.

After the grain is cooked, it sits out on trays to let any excess moisture dry, then it is bagged and sterilized.

The sterilization process can cause the grain to expel excess moisture but this is usually reabsorbed as the bags cool down.

We also suspect shipping in extreme climates can cause abnormalities in the moisture content of the grain as well.

We are taking steps to ensure we are not putting out grain that is too wet and we adjust our cooking time due to the weather/seasons.

What do I do to get the kit to fruit? Taking it from incubation to fruiting stage

To take your kit from a vegetative (incubation) stage to the fruiting stage you need to change four variables, temperature, oxygen levels, humidity and light.

General you want to lower the temperature about 10-15 degrees from the incubation temperature.

This will vary depending on species. Oxygen levels are changed by opening the bag and allowing the kit to get some fresh air.

This is only necessary to do once or twice a day.

For the most part the kit needs to breathe through the filter patch.

Next, the humidity level needs to increase. This is done by misting the inside of the bag once a day.

You will need to be very carful not to over saturate the kit.

You want to see water droplets on the inside of the bag walls but not water pooling up on the substrate.

Last is light, and this can be done by moving it somewhere which to get a few hours of indirect sunlight every day.

Do not place the kit in direct sunlight.

A soft white light bulb is a more than sufficient light source.

Should there be water drops / condensation in the bags

Some condensation in the bags is normal.

Especially if shipped in extreme temperatures, bags can sweat out moisture.

As long as there is no liquid pooling up at the bottom of the bag you will be fine.

Just allow your bag to sit at room temperature for a few days after shipping before using to allow the moisture to reabsorb into the substrate.

Should the grains be mushy / the grain is too soft

The grains will be somewhat soft just due to the fact that they have been cooked but they should not be mushy. Think more of the texture of cooked rice and not mashed potatoes.

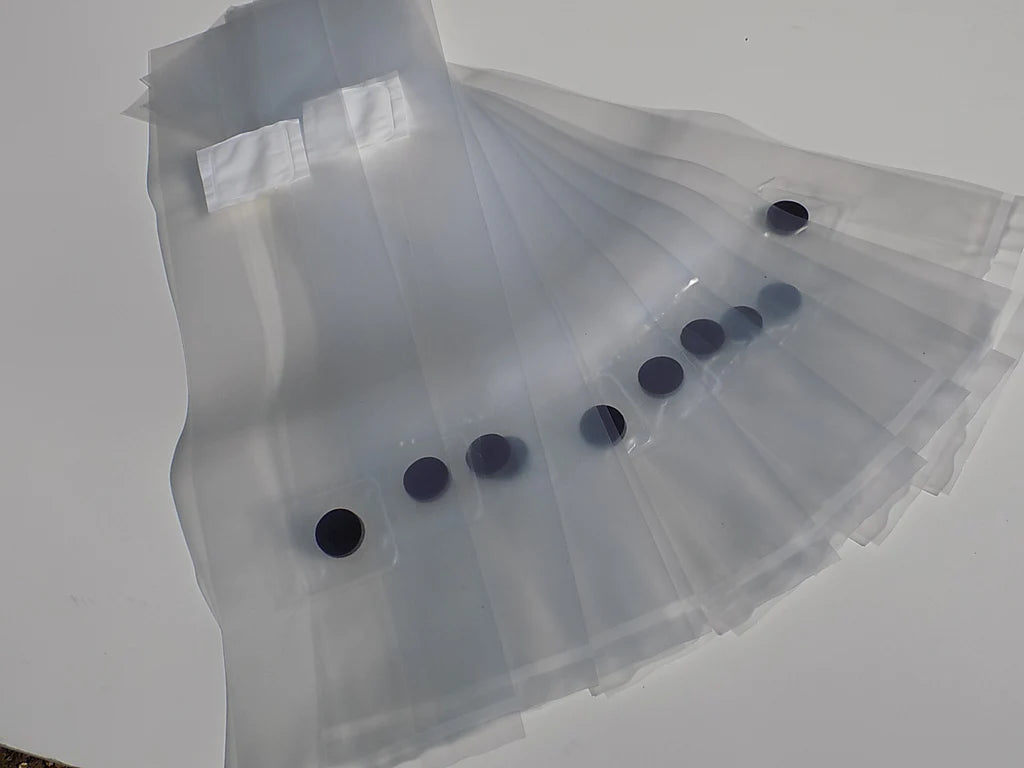

Grain to grain transfer

Open each bag and pour the colonized grain into the sterilized bag with about a 10 to 1 ratio.

Much like you do when inoculating compost.

One fully colonized bag of grain can in turn go on to inoculate 10 bags, and those 10 bags can inoculate 100 bags and so on.

This will allow you to always have colonized grain available and eliminate the need for spore syringes.

This will lead to a greater yield in a smaller turn around time.

We do not use spore syringes on our farm rather liquid cultures and grain to grain transfer.

The only downside is because you need to open the bags to transfer them, you must do this in a sterile environment.

Preferable with a laminar flow hood to prevent contamination.

We completely understand how frustrating it can be when bags do not produce.

However, have you tried testing your spores on a petri dish to ensure they are free of mold or contaminates?

It doesn’t matter how sterilized the needle is. If bacteria is in the syringe itself it will contaminate your bags.

We suggest not starting with spores but use a liquid culture or do grain-to-grain transfers.

This way you are starting with a live living culture and you will be able to see if there is any contaminates growing on it.

Another important thing is to make sure you are working and growing in a clean environment.

Do you have a HEPA filter or use a laminar flow hood?

Making sure the surrounding air is clean is a step that a lot of people overlook.

Spraying disinfectant will not necessarily clean 100% of the air in your work environment.

Especially if you have air circulating in the room such as from an air conditioner vent.

What temperature do I incubate my culture at

First off, different mushroom species will require different temps for incubation.

As some are tropical species and others can grown Alaska etc…

A general rounded amount is to incubate the mushrooms between 75-85 and then fruit around 65-75.

This is not exact but what we would advise doing is to google the growing conditions for the individual species you are trying to grow.

This will help you find the most optimal temperature for incubation.

Also, if you are not familiar check out a website called www.shoomery.org

We are a sponsor of the site.

They have a vast message board where you can find tons of useful information of growing just about any species you can think of.

Contact us

Located East Of Cincinnati, Ohio

1002 Heiserman Rd

Milford, Ohio 45150

Monday thru Friday: 10am - 4pm

Weekends: Closed